Supply chain sustainability with Attribute Based Planning

With very few exceptions, in today’s businesses sustainability is where quality was 40 years ago. Quality is no longer just the quality manager’s job, everyone is responsible for quality. It is an integral part of operations. When it comes to sustainability, it is critical to have an end to end view of the supply chain, otherwise what carbon footprint you save in operations might be added, and then some, in transportation and packaging.

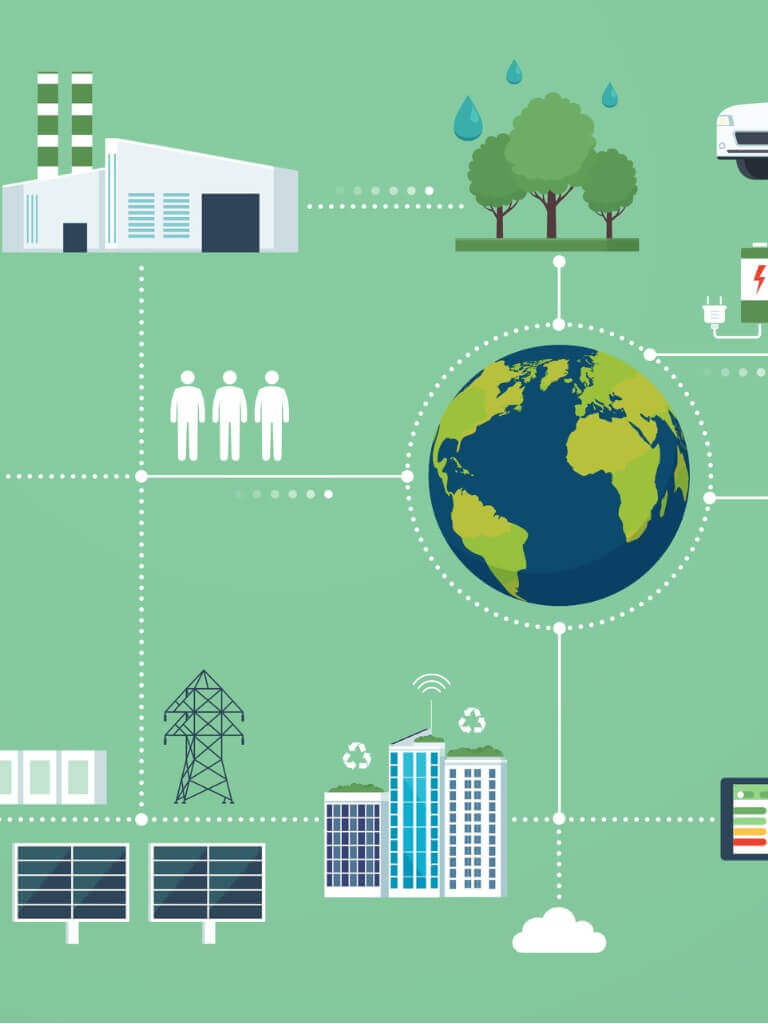

With Attribute-Based Planning (ABP) technology, corporations are enabled to use attributes as intelligent constraints to be attached to every entity of the supply chain end to end. An entity can be a supplier, region, transportation methods, equipment, energy use of the plants, a commodity price, regional regulations, or type of packaging, etc.

By attaching a carbon index, relative or absolute, to each entity, every supply chain plan that we create measures and highlights how green the planned operation would be just like how profitable a plan would be. This approach has the advantage of using a digital twin of the supply chain to control the behavior of the physical supply chain. It enforces change management by showing where the big offenders are and what trends are developing as new plans are generated. The digital model constantly guides every entity to see and correct their relative contribution to the carbon footprint of the entire supply chain. Moreover, just like controlling cost of goods sold, using ABP, companies can manage, control and adjust sustainability of goods sold.

ABP technology brings visibility to every single part of the supply chain and makes every operation, supplier and customer aware and responsible for their carbon contribution. It enables better negotiation with suppliers and customers to trend down their carbon footprints and it enforces an integrated culture of sustainability for the entire supply chain end to end.